TM 9-2320-289-34

6-15.

REAR AXLE DIFFERENTIAL MAINTENANCE (ALL EXCEPT M1009) (Con’t).

NOTE

At this point, side bearings are preloaded. If any additional adjustments

are required, ensure that preload remains as established. If 1 adjusting nut

(8) is loosened, the other must be tightened an equal amount to maintain

this preload.

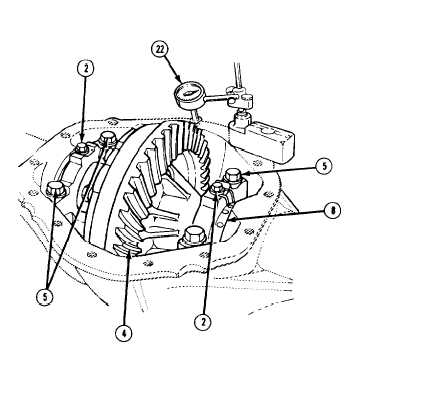

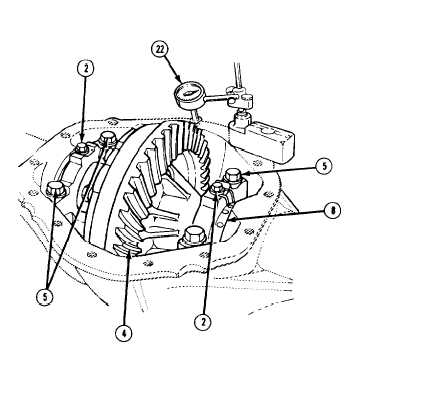

8.

Mount dial indicator (22) on housing

and measure backlash between ring

gear (4) and drive pinion gear. Rock

ring gear back and forth to measure

backlash.

Backlash

should be

between 0.003-0.012 in.

(0.076-

0.305 mm)

with

(0.1 27-0.203 mm)

NOTE

If adjusting nut

0.005-0.008 in.

preferred,

(8) requires

adjustment, bolts (2 and 5) must

be

loosened.

Once

final

adjustments

have been made,

bolts must be retightened to

proper torque.

9 .

If backlash is more than 0.012 in.

(0.305 mm), loosen right adjusting

nut (8) 1 slot and tighten left adjusting

nut 1 slot. If backlash is less than

0.003 in. (0.076 mm), loosen left

adjusting nut 1 slot and tighten right

adjusting nut 1 slot. Remove dial

indicator (22) from housing.

NOTE

If ring gear (4) and drive pinion were replaced, perform steps 10-13 to

check for proper gear tooth contact pattern.

10.

Wipe any lubricant from housing and clean each tooth of ring gear (4).

11.

Using a medium stiff brush, sparingly apply prussian blue dye to all ring gear (4) teeth. Area of

drive pinion tooth contact should be visible when drive pinion is engaged by hand.

NOTE

Excessive turning of ring gear (4) is not recommended. Ring gear should

be turned only enough to provide tooth contact pattern,

12.

Apply load until it takes a torque of 40-50

companion flange so that ring gear (4) turns

turns 1 full revolution in opposite direction.

Ib.-ft, (54-68 N.m) to turn drive pinion. Turn

1 full revolution, then reverse so that ring gear

TA50588

6-102