TM 9-2320-289-34

Table 2-1, Mechanical Troubleshooting (Con’t)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 4.

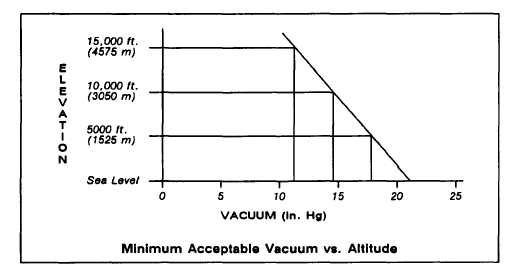

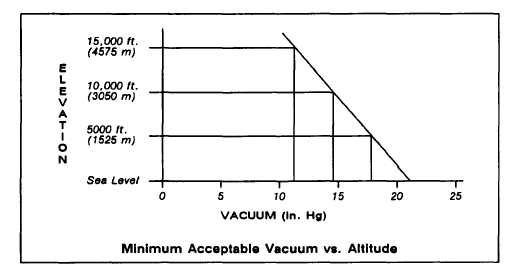

Disconnect vacuum hose from vacuum pump. Install hose and vacuum gage on

vacuum pump. Start engine. Calculate proper vacuum gage reading as shown in

chart. Shut off engine.

If vacuum drops 1 in. Hg or more in less than 1.5 seconds, or if vacuum

never reaches proper gage reading,

replace vacuum pump. (See

TM 9-2320-289-20)

Step 5.

Step 6.

Step 7.

Step 8.

Remove, clean, and inspect vacuum modulator assembly and modulator valve.

(See paragraph 5-3)

Remove and air check direct clutch for leak to outer area of direct clutch

(See paragraph 5-1 7)

Repair direct clutch if it is leaking.

Remove, disassemble, clean,

and inspect transmission oil pump.

piston.

(See

paragraph 5-1 5)

Check for damage to intermediate clutch piston seals, second oil seal ring on

center support, and center support assembly.

Replace any damaged components. (See paragraph 5-1 9)

58. LONG 1-2 SHIFT WITH END BUMP, 1-2 SLIPPAGE, OR EARLY 1-2 SHIFT

Step 1.

Test transmission oil pressure with brakes applied, “ D“ (Drive), engine at

1000 rpm. (See paragraph 5-11)

If oil pressure is normal, perform step 2.

If oil pressure is low, perform step 3.

2-35