TM 9-2320-289-34

Table 2-1, Mechanical Troubleshooting (Con’t)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Step 6.

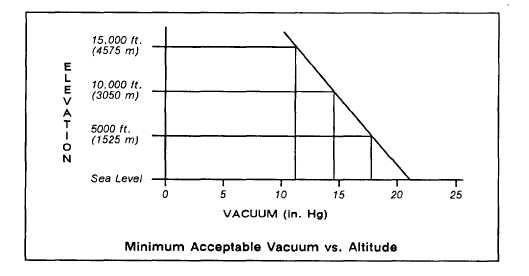

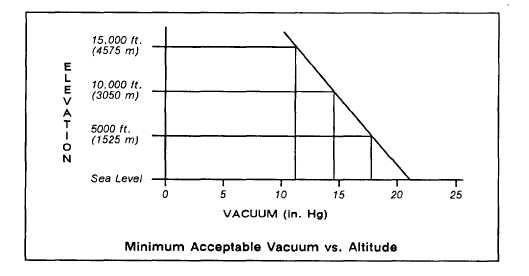

Disconnect vacuum hose from vacuum pump. Install hose and vacuum gage on

vacuum pump. Start engine. Calculate proper vacuum gage reading as shown in

chart. Shut off engine.

If vacuum drops 1 in. Hg or more in less than 1,5 seconds, or if vacuum never

reaches

proper

gage

reading,

replace

vacuum

Dump.

(See

TM 9-2320~289-20)

- -

Step 7.

57. ROUGH 1-2

Step 1.

Step 2.

Step 3.

Remove, clean, and inspect vacuum modulator assembly and modulator valve,

(See paragraph 5-3)

SHIFT OR 2-3 SHIFf

Test transmission oil pressure with brakes applied, “ D“ (Drive), engine at

1000 rpm. (See paragraph 5-11)

If oil pressure is normal, perform step 2.

If oil pressure is high, perform step 3.

Check for loose or damaged detent solenoid,

Tighten detent solenoid if loose and replace if damaged. (See paragraph 5-7)

If detent solenoid is not loose or damaged, clean transmission control valve

assembly. (See paragraph 5-7)

Check for loose or damaged vacuum lines and hoses.

Connect vacuum hoses or vacuum lines if loose and replace if damaged, (See

TM 9-2320-289-20)

2-34

Change 2