TM 9-2320-289-34

5-21.

TRANSFER CASE MAINTENANCE (ALL EXCEPT M1028A1 AND M1031)

(Con’t).

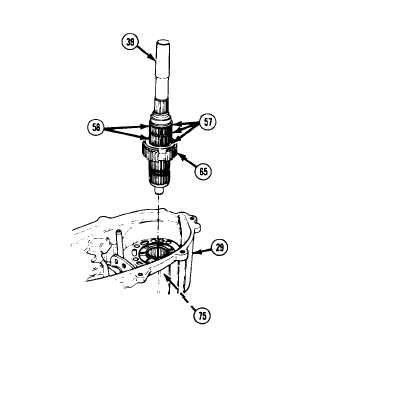

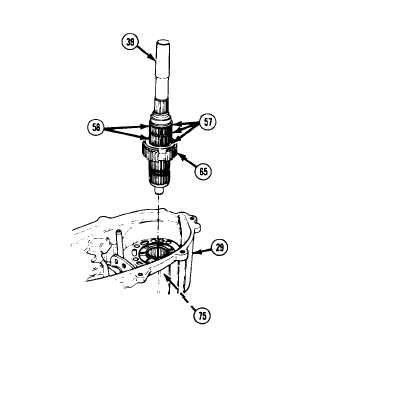

NOTE

Mainshaft (39) should be placed in a soft-jawed vise while assembling

spacers (57) and roller bearings (58).

1

7 .

Lightly coat mainshaft (39) with

petrolatum and install first spacer

(57). Install first row of 60 roller

bearings (58). install second spacer,

then second row of 60 roller bearings.

Install third spacer. Lightly coat

outside surfaces of all roller bearings

with petrolatum to ensure that they

remain in position.

NOTE

Before installing mainshaft (39),

ensure that input drive gear thrust

bearing (75) is properly centered

in

input

drive

gear.

(See

ASSEMBLY, step 11)

18.

Install

mainshaft

(39)

and

synchronizer hub (65) in front case

(29) .

NOTE

Transfer cases manufactured before July 1, 1983 (as stamped on

identification plate) have no straight pin.

19.

Lightly coat straight pin with petrolatum and install to mainshaft (39).

20.

Install mode fork retainer (62) to mode fork (63). install mode fork to synchronizer sleeve (64)

with flat side of synchronizer sleeve facing front of front case (29),

21.

Install mode fork (63) and synchronizer sleeve (64), as a unit, to shift rail (47), engaging teeth

of synchronizer sleeve with teeth of synchronizer hub (65),

22.

Install front output shaft (33) front thrust bearing assembly with thick thrust washer (61 ) next to

front case (29), followed by thrust bearing (60), and thin thrust washer (59). Install front output

shaft.

TA50326

5-152