TM 9-2320-280-34

Section II. ILLUSTRATED MANUFACTURING INSTRUCTIONS (Cont`d)

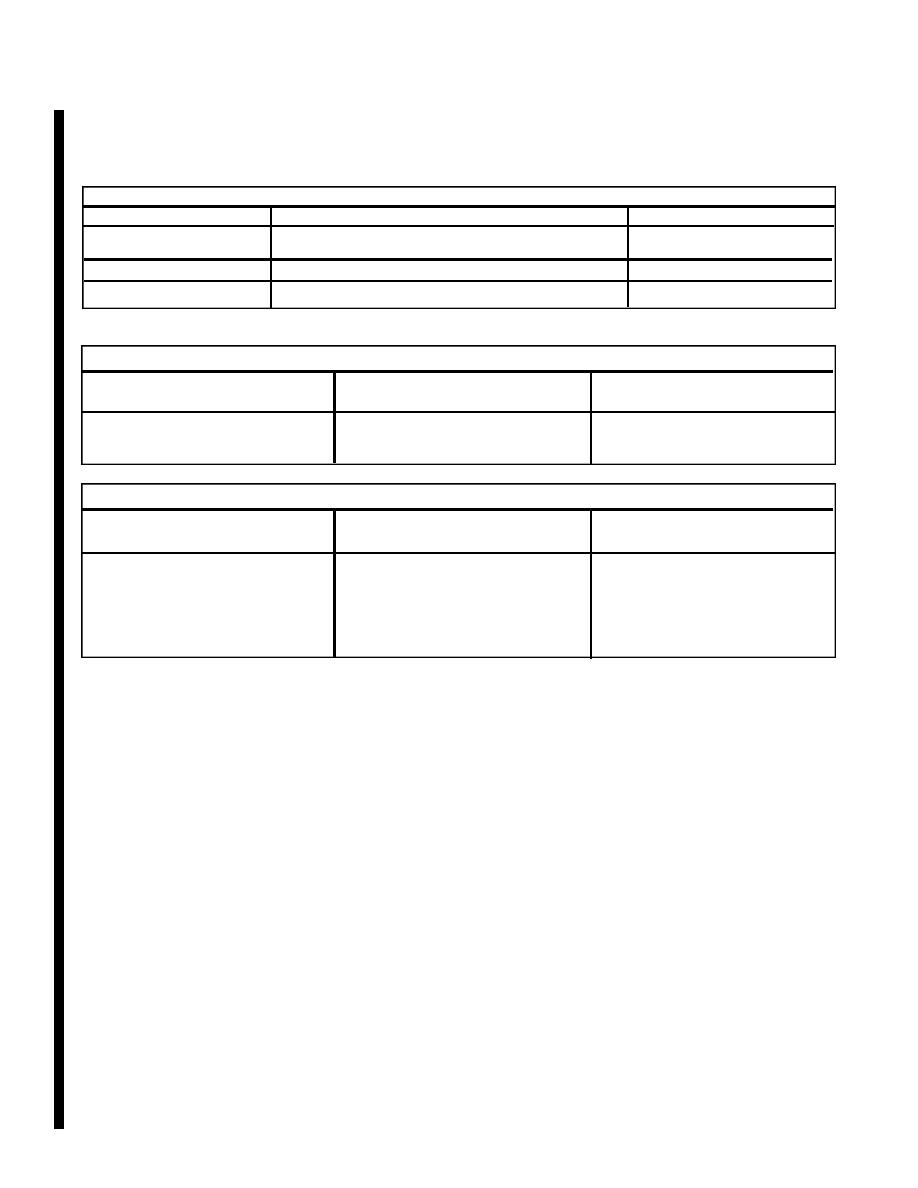

MATERIAL BLOCK

STOCK SIZE

DESCRIPTION

SPECIFICATION

0.625-IN. THICK

BAR, METAL, STEEL

ASTM A108

1.000-IN. THICK

BAR, METAL, STEEL

ASTM A108

0.375-IN. THICK

BAR, METAL, STEEL

ASTM A108

MATERIALS

MANUFACTURED FROM

REQ'D

DESCRIPTION

NSN

2

WASHER, FLAT

5310-01-186-1254

CYLINDER HEAD LIFTING DEVICE

MANUFACTURED FROM

PART NUMBER

CUT TO SIZE

NSN

(INCHES)

N/A

14

9510-00-224-1692

N/A

11.5

9510-00-287-9402

N/A

8

9510-00-596-1405

INSTRUCTIONS:

1. Cut a 14-in. long section (1) of metal bar from NSN 9510-00-224-1692 as shown in figure C-47.

Bend metal bar (1) as shown in figure C-47.

2. Cut an 11.5-in. long section (2) from NSN 9510-00-287-9402 as shown in figure C-47.

Bend metal bar (2) as shown in figure C-48.

3. Cut an 8-in. long section (3) from NSN 9510-00-596-1405 as shown in figure C-47. Locate, mark, and

drill four 0.437-in. diameter holes through metal bar (3) as shown in figure C-48.

4. Remove all burrs and sharp edges.

5. Weld all three metal bars together as shown in figure C-48. All welds will be in accordance with

MIL-STD-1261 Class 2. All weld sizes are minimal.

C-34

Change 1