TM 9-2320-280-34

14-17. AIR-CONDITIONING SYSTEM SERVICING (R-12) (Cont'd)

g. Checking/Adding Lubricating Oil

NOTE

It is not necessary to check or add oil as routine maintenance. It is

necessary to check oil when the evaporator, condenser,

compressor, or receiver/dryer has been replaced, or there was an

obvious oil leak. When a system is discharged, it is also necessary

to replace any oil carried out with the refrigerant.

Vehicle must be on level ground.

1.

Charge A/C system (refer to task f.).

2.

Make sure low pressure gauge valve (1) and high pressure gauge valve (2) on manifold gauge set (3)

are turned clockwise to off position.

3.

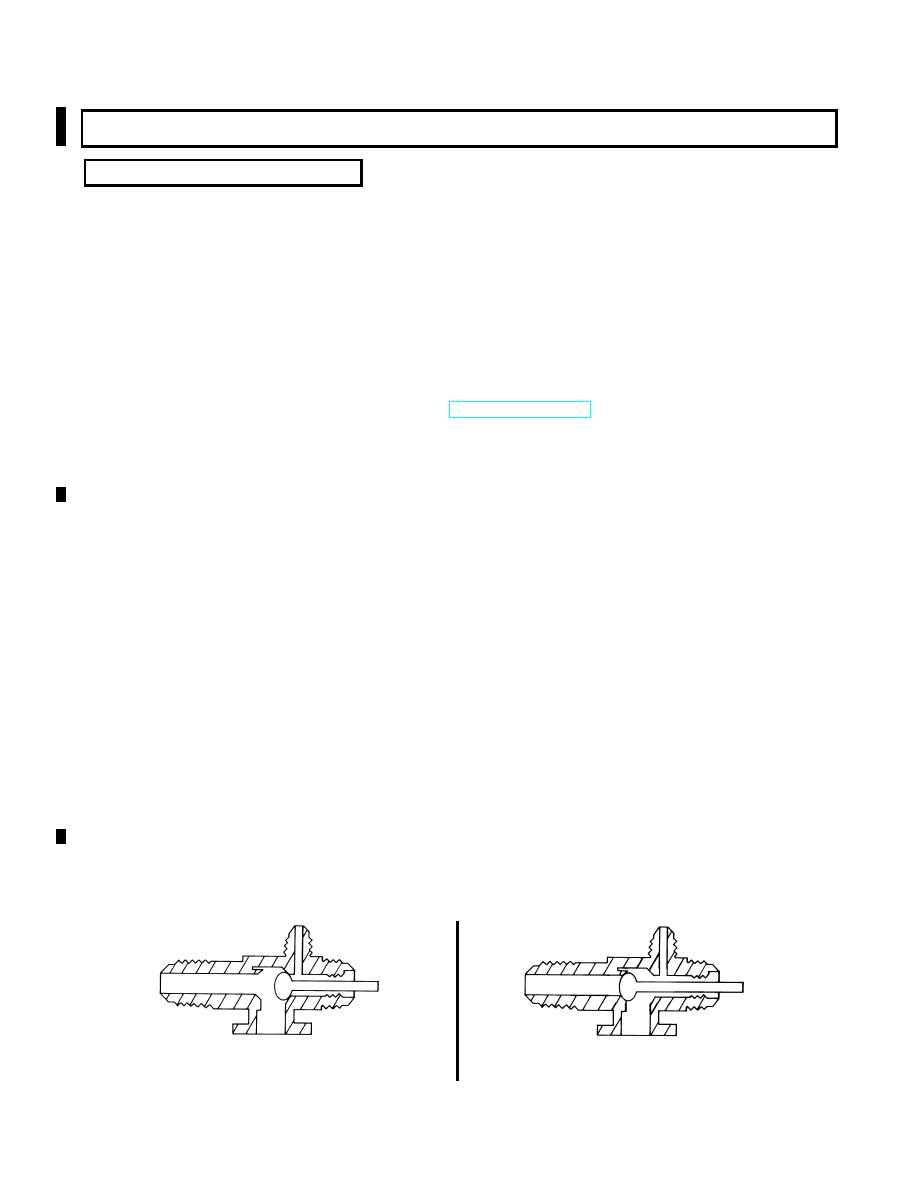

Turn two service valve shafts (6) counterclockwise to back-seated position.

4.

Start engine and turn on A/C system (refer to TM 9-2320-280-10). Allow engine to idle for

approximately ten to fifteen minutes. Stop engine.

5.

Turn two service valve shafts (6) clockwise to front-seated position.

NOTE

Do not allow refrigerant R-12 to escape too quickly. Lubricating oil

will escape.

When high pressure gauge and low pressure gauge read "zero",

the compressor is discharged.

6.

Turn low pressure gauge valve (1) and high pressure gauge valve (2) counterclockwise slightly to

permit refrigerant in the compressor (5) to slowly escape through center hose (4) until gauges

read "zero".

7.

Close low pressure gauge valve (1) and high pressure gauge valve (2).

8.

Remove fill plug (7) and O-ring (8) from compressor (5). Discard O-ring (8).

9.

Look through fill plug (7) hole in compressor (5) and rotate front clutch plate (9) with ratchet and

socket to position internal compressor parts, as shown. Planet plate should be positioned so that

dipstick can be inserted to full depth.

10.

Insert the dipstick to its stop position, as shown. The stop is the angle near the top of the dipstick.

The point of the angle must be to the right, and the bottom surface of the angle must be flush with

the surface of the filler hole.

11.

Remove dipstick from compressor (5) and count number of increments oil level is up to on dipstick.

12.

Oil level should be between six and eight increments on dipstick. Add or subtract oil as necessary to

attain proper level.

13.

Lubricate O-ring (8) with lubricating oil and install O-ring (8) and fill plug (7) on compressor (5).

Tighten fill plug (7) to 6-9 lb-ft (8-12 Nm).

14.

Remove manifold gauge set (refer to task b.).

SERVICE VALVE IN

SERVICE VALVE IN

FRONT-SEATED POSITION

BACK-SEATED POSITION

14-100

Change 2