TM 9-2320-280-34

Table 2-1. Mechanical Troubleshooting (Cont' )

d

MALFUNCTION

TEST OR INSPECTION

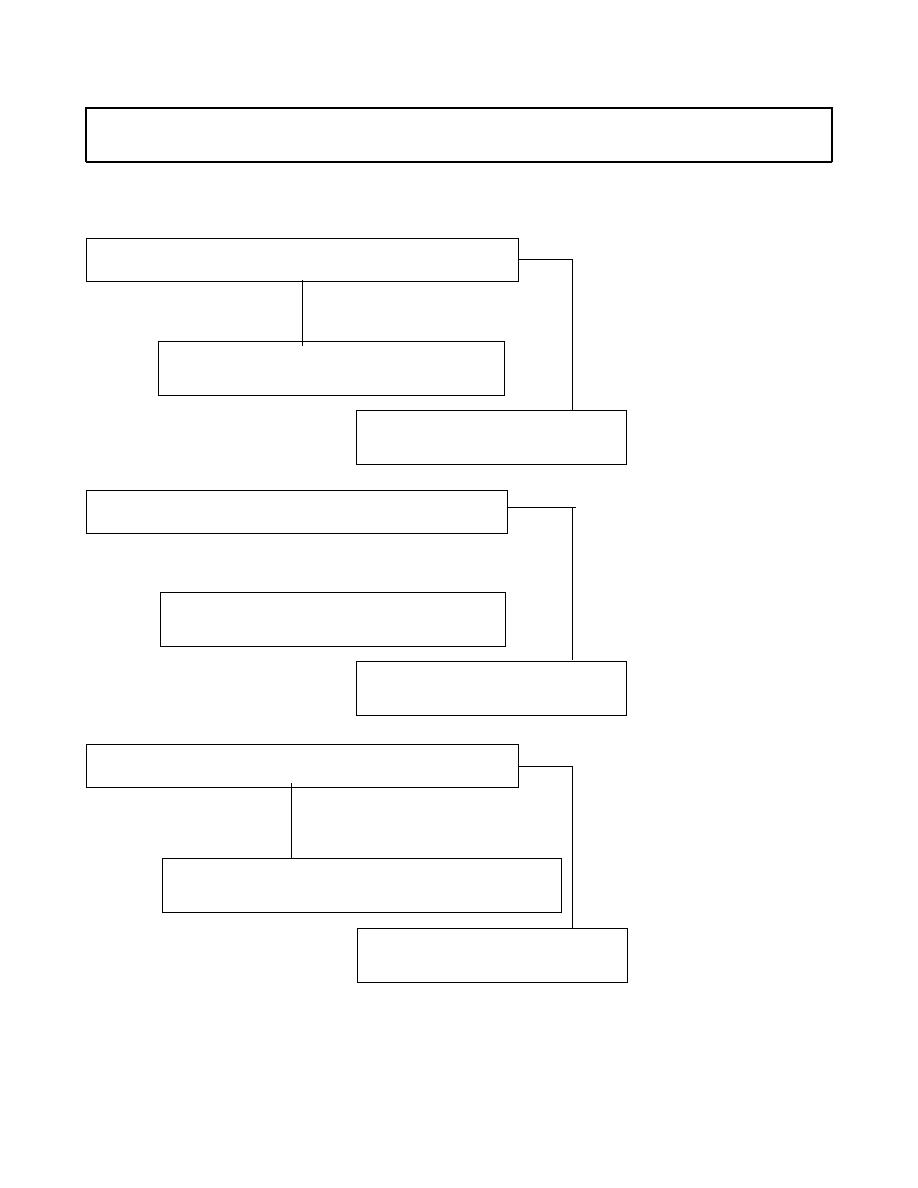

ELECTRIC CHECK-OUT OF ELECTRONIC COMPONENTS IN 4L80-E TRANSMISSION AT

TRANSMISSION ELECTRICAL CONNECTOR.

SHIFT SOLENOID A (1-2)

With the transmission electrical connector disconnected, measure the

resistance between pins A and E. Resistance should be between 18 to 24 ohms.

LOW

HIGH

Check for:

- High resistance of solenoid; replace.

- Bad connections and/or wires to the solenoid; repair or replace.

Check for:

- Low resistance of solenoid; replace.

- Shorts in wires or connectors; repair or replace.

SHIFT SOLENOID B (2-3)

With the transmission electrical connector disconnected, measure the

resistance from pin B to pin E. Resistance should be between 18 to 24 ohms.

LOW

HIGH

Check for:

- High resistance of solenoid; replace.

- Bad connections and/or wires to the solenoid; repair or replace.

Check for:

- Low resistance of solenoid; replace.

- Shorts in wires or connectors; repair or replace.

FORCE MOTOR (PRESSURE CONTROL SOLENOID)

With the transmission electrical connector disconnected, measure the resistance

between pins C and D. Resistance should be between 3.5 to 5.0 ohms.

LOW

HIGH

Check for:

- High resistance of solenoid; replace.

- Wires and connectors for bad connections and or breaks; repair or replace.

Check for:

- Low resistance of solenoid; replace.

- Short in wires or connectors; repair or replace.

2-12.1